We are the experts for customized power supplies.

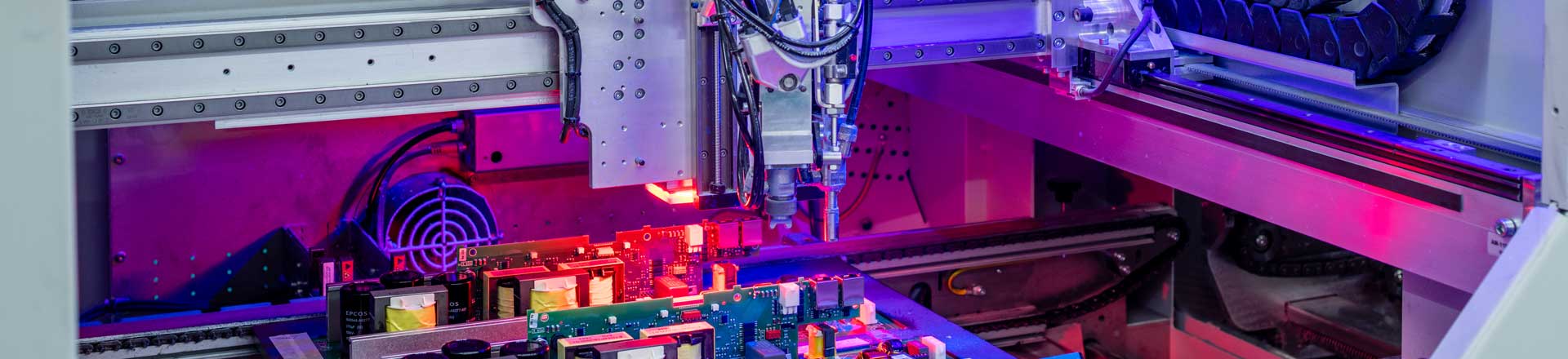

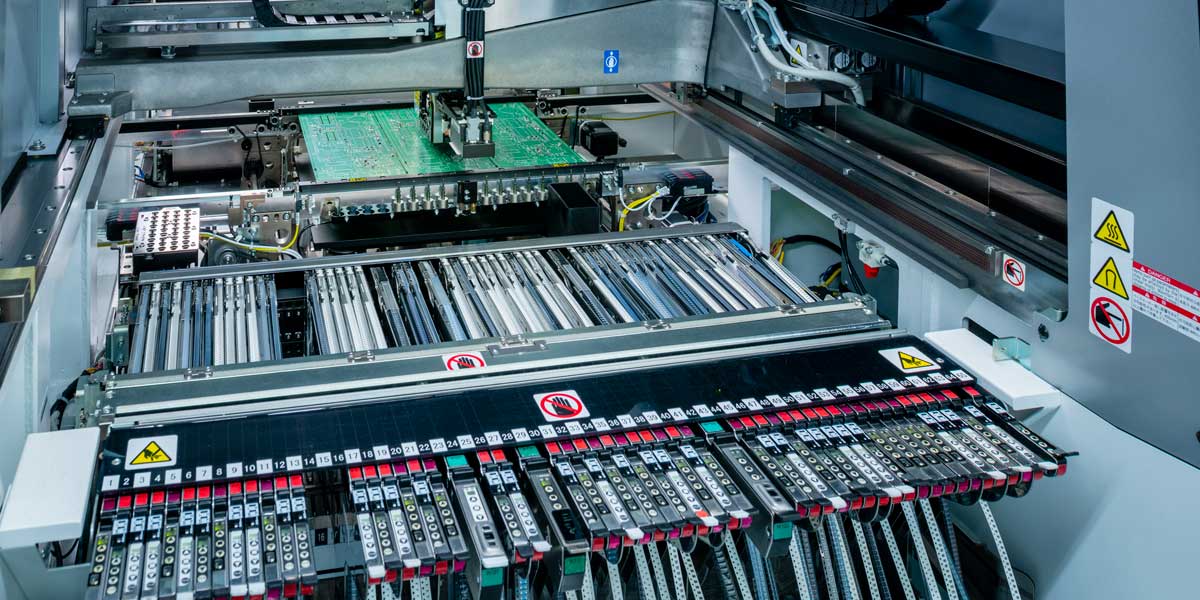

We have decades of experience in the development and production of customized power electronics for medical technology, lighting and special industrial applications. Numerous international corporations, market and innovation leaders have relied on us and our products for many decades. With our powerful development team and semi-automated production at our Nuremberg site, we are ideally positioned to meet the challenges of the future. With the high quality and reliability of our power supplies, we guarantee our customers maximum reliability, low maintenance costs and above-average running times.

Our core competencies

Our development engineers all have a high level of training and extensive expertise in all areas of modern power electronics. They are the right contacts for specifications that are difficult or impossible to implement with the standard products available on the market or customized standard solutions. Our modern and flexible production processes enable fast and efficient small and medium series production as well as mass production in our own factory.

Schiederwerk power supplies. As individual as the end product

Our individually manufactured products are characterized, among other things:

- 100 % Made in Germany

- Efficiencies of over 96%

- High achievable performance parameters

- Highest quality and reliability

- Compact, customized designs

- Innovative, effective cooling concepts

Our customers supply a wide range of products with our power supplies:

- Laser systems

- Crash test lighting

- Solar simulations

- UV-LED drying systems

- Measuring instruments

- Transmission technology

- Battery balancer (charge equalizer)

- Medical devices such as X-ray equipment, ultrasound equipment, operating theater lighting, dental treatment units and operating tables

- Sports and large-area lighting

- Studio and stage lighting

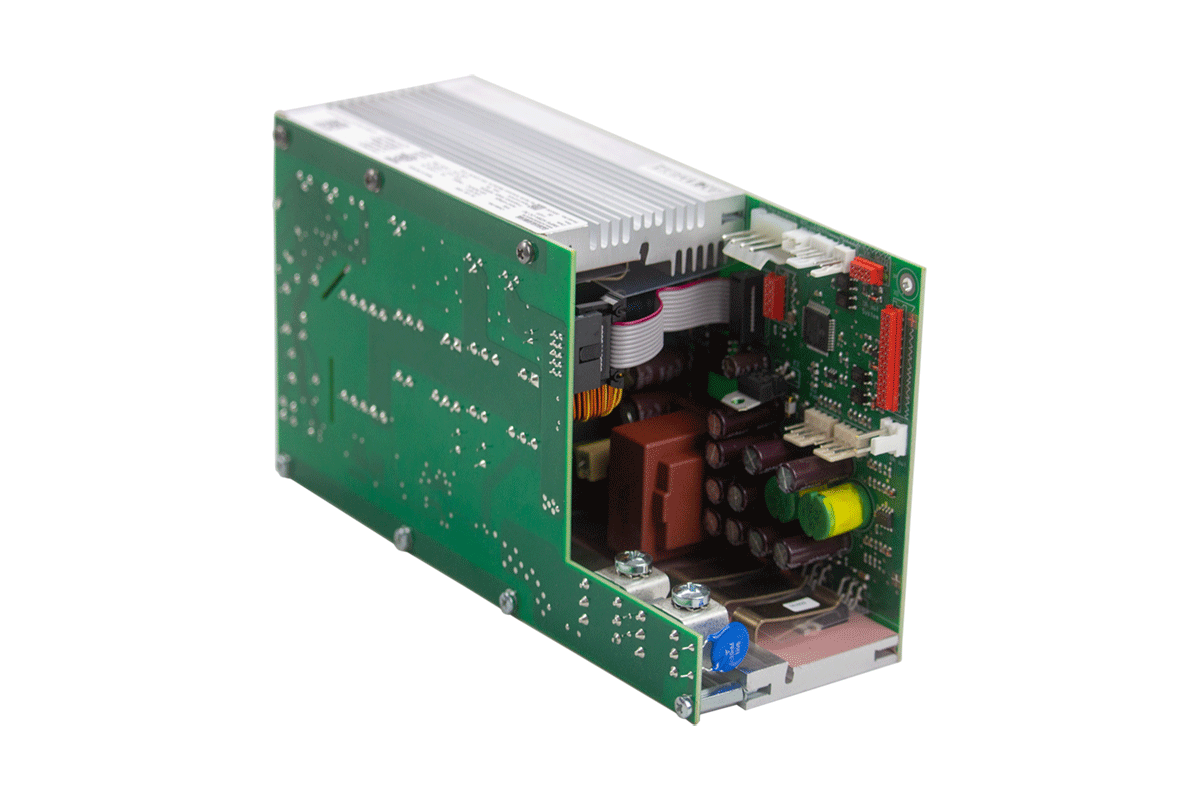

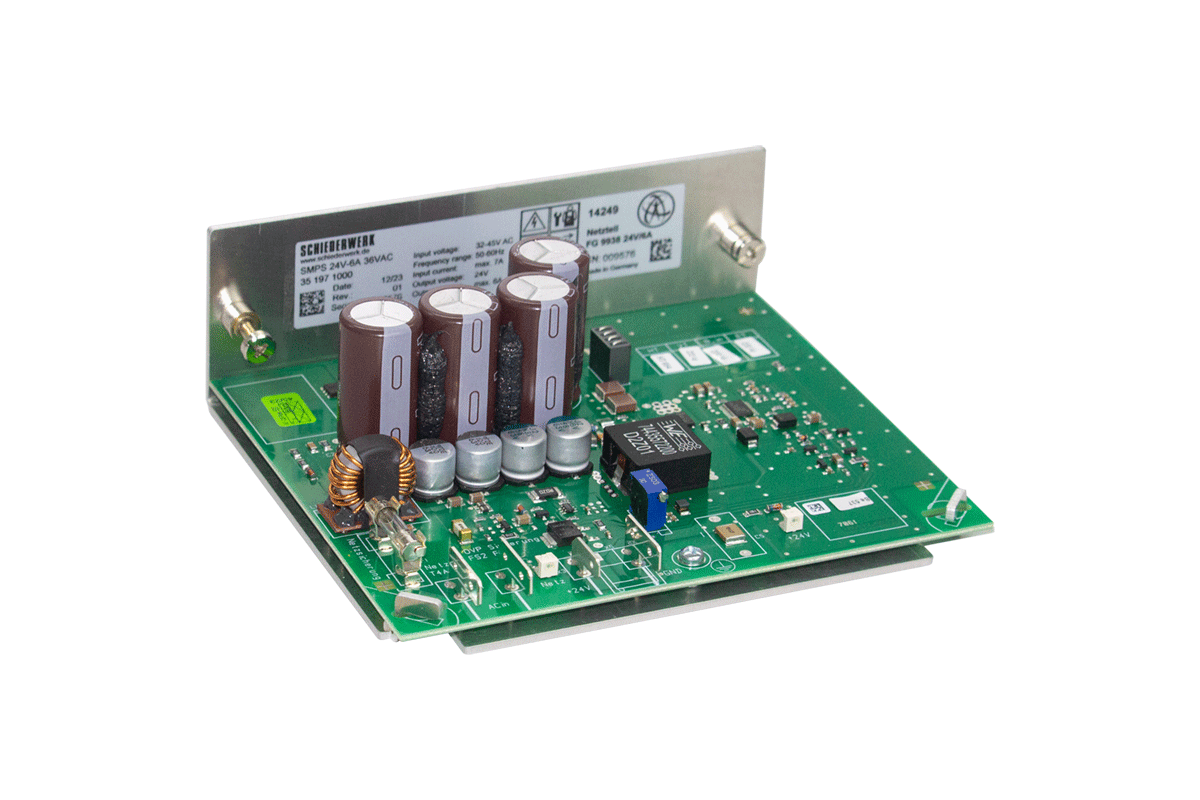

Typical products. Made by Schiederwerk

We are the right partner for power supplies with challenging performance parameters, difficult subsequent application scenarios, unusual designs and specifications far removed from the standard. Our range of services extends from simple PFCs and SMPS to complete plug & play power supplies in UL-certified control cabinets.

High-voltage power supply unit for plasma generator

- 20 kV output voltage (pulsed)

- 700 W output power

- Control interface

- Output pulse frequency range 40 – 80 kHz

LED drivers in large-area lighting

- Output currents up to 30A

- Output voltages up to 750V (1,000V)

- Output power over 1,500W

- Analog or digital control inputs

- Single and multi-channel applications (RGB)

- Additional functions and interfaces (e.g. DMX, RS-485, DALI)

- Various input voltage ranges

- Complete hardware and software development by us

UV LED drivers for the printing industry

- Up to 3,200W output power

- Constant current regulated outputs for UV LED

- Multioutput devices

- Linear and PWM control

- Internal monitoring functions

- Low noise development

Development and production under one roof

We are a one-stop supplier. We make this possible by having all departments working together under one roof at the Nuremberg site: from the development department, which lays the foundation for our successful products, to our entire production, the test laboratories and our own test equipment and fixture construction. As a manufacturer of power supplies and power electronics, we therefore guarantee that all our products are “Made in Germany”. The close proximity of colleagues ensures short distances. All employees involved in a project are in constant personal contact.

The result: fast response times and the ability to react promptly to changing customer requirements at every stage of the product life cycle. This enables us to meet our customers’ highest quality requirements. Our customers from industry and medical technology particularly appreciate this.

Individual development.

Beyond standard products.

The majority of our customers are innovation leaders in their segment. They are often market leaders in a specific niche in their industry, for example in the field of special UV drying processes or innovative applications in medical technology. Even if the end products are very different, the development tasks are often similar. In most cases, our customers have individual requirements for the power supply of their products. The special requirements can only be met to a limited extent or not at all by “off-the-shelf” or customized standard products. That is why we develop individual power supplies that are tailored to the needs of our customers. Whether special input and output parameters, special operating conditions or challenging available space in the end device – our development engineers will find the optimum solution.

Professional and personal exchange

We develop customer-specific power supplies at eye level and guarantee a successful end product through constant, trusting exchanges with our customers. Your most important contact: our development engineers. They accompany you throughout the entire project – from the first briefing meeting, through sample and pre-series production, to the end of the product life cycle. They all have extensive specialist knowledge and in-depth industry expertise. This makes them valuable discussion partners for our customers and important sources of ideas for the internal specialist departments.

Our development engineers are always available internally and externally as direct contacts. Customer-specific requirements and change requests can thus be incorporated unfiltered into the development process. We try to avoid changing the development team responsible for the project as far as possible. In this way, we ensure a high level of production reliability throughout the life cycle and can react quickly and efficiently to changing requirements.

Contact our experts.

Together we develop your individual power supply according to your requirements and specifications.

Do you have any questions?

Please feel free to contact us directly.

Our team will be happy to help you with any questions you may have about your individual power supply. Get in touch with us now!